ALCHOHOL PRODUCTION – A VIEW

In Maharashtra around 16 industries have received licenses to produce alcohol from food grains, besides to this 210% subsidy has been offered. These industries will produce potable alcohol from food grains, which will be purchased from adjacent farmers & also offer them good rate. This activity will create a whooping quantity of 118 Core Liters alcohol for the 11 crore residents of Maharashtra, which has to be consumed in this state only.

ALCOHOL PRODUCTION – ECONOMICS

For production of 1ltr alcohol, we require 3 kg. of Maize at an average rate of 10/- kg. Average rate of potable alcohol is @ 35/-liter. If the cost of raw material is 30/- and we have to add cost of production & profit of the entrepreneur ,this will not be a viable option, hence a subsidy is required to make this viable, then how one can offer good rate to farmers?. As per available data @ 20% of the total yield of any farm is wasted due to handling, lack of storage facility, losses in transport etc. A single example of wastage of wet food grain in the state Haryana is @ 20 lakhs tons last year.

A SUSTAINABLE OPTION – BIO GAS

To produce ethanol from sweet sorghum or Maize and Molasses from sugar industry is not new to us but we are using ethanol in automotives@ 5 % only. While nations like Brazil are using ethanol 100 % & replaces existing fuel completely.

Since our research & development for last 10 years regarding biogas and its related fundamental parameters such as feeding material & its starch content & the bacterial count for degradation. Time required for degradation and so on. We have concluded the production of Biogas from waste food grain on a commercial scale will be economical, environment friendly and can be applied anywhere in India. Though it needs huge capital investment for infrastructure but we have proved the same can have high rate of returns.

Before going into details of the above mentioned project, we must understand what is biogas & how it can be produced , what are the affecting parameters on it etc.

A simple definition of Biogas is “A gas produced from any starchy biomass under anaerobic condition with the help of anaerobic bacteria.” The most known application is “GOBAR GAS” which produced with the same principle from Dung of Animals.

The affecting parameters are mentioned below.

1. Anaerobic Status of Digester Tank

2. Availability of Starch into biomass.

3. Time required for Biodegradation (Hydraulic Retention Time)

4. Total number of Anaerobic Bacteria

5. Temperature of Digester Tank @ 25C0 (Low Temperature Affects Bacteria’s)

The feed quantity of Biomass into Digester Tank of Biogas Plant is further degraded with the help of three type bacteria’s. Those are mentioned below.

(i) Hydrolytic Bacteria

(ii) Acidogenis Bacteria

(iii) Methanogensis Bacteria

Acetic Acid is formed by bacteria (CH3COOH) which is further degraded and two Gases (CH4) (Methane) & CO2 (Carbon dioxide) are produced in a combination of Biogas.

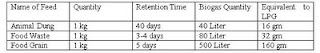

If we consider two different Feed Material for Biogas (a) Animal Dung (b) Food waste. (c) Food Grain. Let us compare the production of Biogas from the table mentioned below.

Earlier residents of rural area, who were using biogas, makes a complaint regarding burning of Biogas. This was true because biogas contains 60 % Methane (CH4) & 40 % Carbon dioxide (CO2) due to the non burning of Carbon dioxide an adverse impact on the flame of biogas resulting slow burning.

At “Shashwat Oorja” Pune with a continuous research and development in the same, we have separated both the gases successfully where the burning of Methane becomes complete & even the calorific value of biogas is increased. As both gases are separated we have successfully implemented their refilling into cylinders which will double the economics of the plant by selling CO2.

As Carbon dioxide has its own usage in different industries like forging, welding, Extraction solvency, Aerated drinks & dry ice, the rates for CO2 also different from 15 to 100 /kg depending upon application.

In these projects, it is not necessary to use good quality food grain, but wastage in grains, low quality food grain, wet waste of food grain can be used to produce biogas. This will become an additional income for farmers though which they will generate wealth from waste. This may be a small attempt to save pollution but will add same cash benefits like Carbon Credit Certificate. (C.C.C.)

Any farmer can install & use these plant. They are Eco friendly and Tech friendly. The farmers can cultivate some of the energy crops in their farm. Such as Tapioca, Maize, Sugar beet to produce highly starchy biomass. This will ensure the high rate for crop at the field / farmer itself. These energy crops produce high quantity of biogas as 900, 500 & 300 liter/kg respectively.

The slurry generated for biogas plant can be recycled in the farm to increase C: N ratio along with N.P.K. contents of the soil which will enhance the yield of crop.

As the 70% of our total L.P.G. (liquefied Petroleum Gas) is imported, we can offer a local & sustainable option of fuel to citizens of India. This will also save high expenditure on resources of our India.