Thursday, March 27, 2014

Tuesday, April 23, 2013

bio gas book in marathi

a new book on biogas in marathi

to all,

Monday, July 11, 2011

ECO-FRIENDLY CYCLE OF SUGARCANE FARMING

Deepak Kanhere

ABSTRACT

When agriculture waste is decomposed, the important gases are vaporized & get wasted. In this article, we will see hoe biogas can be produced by anaerobic digestion of various agri. wastes such as sugar factory effluent, distillery’s spent-west, sugar beet, sweet-sorghum etc. Not only will methane be used for electricity generation but Carbon Dioxide can be used in Agriculture for enhancing production.

In the year 2010-11, there was a bumper yield of sugarcane because of better rains in the monsoon. Higher sugarcane production resulted in an additional production of sugar in all the sugar industries. Due to this, huge molasses was generated. Today almost all the sugar industries dispose the molasses through their distillery units to produce alcohol.

Since the distillery units have produced additional quantity of alcohol, still the question of disposal of spent wash remains unanswered. We at Shashwat Oorja not only believe into eco-friendly and sustainable options but also we behave.

For the disposal of spent wash the process of Anaerobic Digestion (A.D.) is preferred and adopted by sugar industries through co-generation plants on mega watt scale where Biogas is combusted in the generators. We carried some different experiment and found the amazing results.

Though the process of A.D. of spent wash results into good quantity of Biogas while combusting through generators, we adopted the process of enriching Biogas (i.e. separation of Methane). If we analyze the contents of Biogas then….

Methane is 58 - 60%

Carbon dioxide is @ 38 - 40%,

And traces of hydrogen sulphide, ammonia, sulphar dioxide and moister.

To increase the calorific value of Biogas we separated methane from Biogas through a process called water scrubbing. At the same time the high quantity of carbonated water generates. We applied a prototype plant for re-capturing the carbon dioxide from this carbonated water.

Let us understand the weight and volumes of 1 meter cube Biogas.

a) Methane @ around 60% i.e. 600 liters which is 384 gms,

b) Carbon dioxide @ around 40% i.e. 400 liters which is 600 gms, and

C) Traces of hydrogen sulphide, ammonia, sulphar dioxide and moister is around 16

gms by weight.

After the separation of methane and carbon dioxide the calorific value of methane increased in the comparison with normal biogas. But the question of carbon dioxide disposal arose. The technologists are well aware about the usage os carbon dioxide in different industries such as………

a) Porous agent in casting industry

b) An extraction solvent

c) An agent in tigmig welding for non-oxidation

d) Carbonated water in soft drink industry

e) Dry ice for cold chain etc……

These utilities of carbon dioxide in industries are limited as far as the produced quantity of carbon dioxide as a byproduct in other industries is concerned.

We carried out some experiments in different farms for different crops at different seasons in the year.

• At present the available percentage of carbon dioxide in air is @360 - 370 p.p.m. - is

• We increased this percentage by 330 - 340 p.p.m. to reach a maximum level of 700 p.p.m. of carbon dioxide in air.

• This resulted an increase in crop yield from 10 - 18 % depending upon the type of crop of the range C-1, C-2, C-3, & C-4.

• For this we sprayed carbon dioxide in gaseous form approx @ 5 kg per acre.

• The adverse effect was also observed in the case where level of carbon

dioxide went beyond 700 p.p.m., the yield went down.

As everybody knows if the proper quantity of carbon dioxide is offered to the plant the rate of photosynthesis increases and so does the increases in vegetative production which results in high production of food to the leaves.

Another observation of carbon dioxide usage in farm has altogether different perspective. As we sprayed the carbon dioxide in late evenings the entire area nearby to the bottom of crop was highly carbon dioxide enriched and the same helped to get rid of all the insects on the plant by killing them.

At Shashwat Oorja. We believe in innovative experiments and to share our end results with requisite persons by providing the most eco-friendly and sustainable options.

Monday, February 28, 2011

POSSIBLE SOLUTION FOR SUGAR INDUSTRIES’ EXCESSIVE MOLASSES’

POSSIBLE SOLUTION FOR SUGAR INDUSTRIES’ EXCESSIVE MOLASSES’

In our society, there are number of problems and also there are number of solutions available in the same society. The need is of paradigm shift so that the solution and the problem can be rightly matched. Today all the sugar mills have a disposal problem of excessive molasses’ generated by them. Deepak Kanhere, Pune based engineer has supported a very simple and viable eco-friendly solution on this so called difficult problem.

Due to extended monsoon there was a heavy production of sugarcane and hence the cane harvesting schedule also got extended. With the increase in sugar production significantly, the problem of excessive molasses’ which is a byproduct of sugar arose. When the director of co-operative department permits sugar mills to enhances their capacity then had they not considered the disposal or storage issue of the excessive molasses’ produced by these sugar mills ? One can understand their own profitability and economics involved in the molasses’ based distilleries. Through the process of methanogenisis there are many cogeneration plants running on spent wash which is a byproduct of these distilleries and are generating electricity on Biogas.

What to do with this excess molasses’? This question was raise in an article published by Agro One; looking at the figures in the article we hereby are providing a suitable and sustainable eco-friendly option available for the said problem.

No. of sugar mills in

Indisposed molasses’ available : 1.2 millions M.T.

Referring these figures we can say that every sugar mill has to dispose 7400 M.T. of molasses’ per annum. This simply means disposal of 20 M.T. of molasses’ a day is a concern to every sugar mill.

This illustrates further as mentioned below.

· 1 kg of molasses’ produces 500 liters of Bio gas.

· 20 M.T. of molasses’ will produce approx. 10,000 M3 of Biogas every day.

· 12 M3 of Biogas requires generating 1 KW of electricity.

· Considering the daily production of 10,000 M3 of Biogas, approx. 0.75 MW electricity can be generated by single sugar mill in one day.

· In a whole year one sugar mill can produce approx. 135 MW of electricity that to in a completely decentralized form.

· The slurry disposed by the Biogas plant is excellent liquid manure for organic farming which will further reduce the Salivation effect on land.

· Since daily production of Bio-gas is above 10,000 M3 the same is entitled for Carbon Credit Certification. (C.C.C.) worth Rs. 2.5 crore per annum.

· The revenue generated through C.C.C. is every year vis-à-vis subsidy is one time only.

· The entire plant is eco-friendly and the electricity generated by the sugar mills in a year will resolve the power shortage issue of

· With these economics and viability there is no need to beg for any financial support to the government.

If we understand the severity and intensity of the problem then this can be most suitable solution which is putting the government of

Economical Biogas Plant for Household

A Pune based engineer Deepak Kanhere has developed a new Biogas model for the citizens of urban area, for whom availing Biogas plant can be a very easy option. Since he has developed an economical Biogas plant just for Rs. 2500/- this can be most easy for the nuclear families.

A Pune based engineer Deepak Kanhere has developed a new Biogas model for the citizens of urban area, for whom availing Biogas plant can be a very easy option. Since he has developed an economical Biogas plant just for Rs. 2500/- this can be most easy for the nuclear families. From last 10 years he has been engaged in research and development of Biogas for which he founded “Shashwat Oorja Private Limited” in January 2008.

While speaking to Maharashtra Times Pune correspondent he reiterated the usefulness of this gadget for every household since it can cater its wet garbage in a range of half kilogram to two kilograms a day.

This compact Biogas plant comprising of 100 liters capacity PVC tank as a digester and 80 liters capacity stainless steel barrel as a gas holder. Besides this it has inlet pipe for feeding and an outlet pipe for slurry disposal. Half inch gas cock is fixed on top of the gas holder which is then connected to a single burner stove by means of a flexible PVC pipe.

Anyone who uses this Biogas plant can use food waste or leftover food, used tea powder, grain flour, peeling of fruits, vegetables in the plant which will roughly deliver 80 liters of Biogas per kilogram of feed material. The slurry disposed by the Biogas plant can be filtered easily and the same water can be reused for next day’s feeding. The filtered biomass is excellent manure which can be used for plants.

While talking to our correspondent he highlighted this as a good opportunity for the Self Help Groups (S.H.G.) of women through which they can generate an additional income for their groups and can further push awareness of this useful gadget to the society. At the same time this Biogas plant can be used in number of schools where the leftover food in the tiffin is taken cared and the produced Biogas can be used in Bunsen burner in the laboratory to carry out various heat related experiments done by the students. With this the school itself can become energy independent. Shashwat Oorja has a firm belief that being a part of society the problem crated by us need to be resolved by the individuals of the same society. And hence we are ready to guide for any such activity with a nominal fees as this is totally an environment friendly project said Deepak Kanhere.

Thursday, October 7, 2010

FUEL OR WINE FROM FOOD GRAINS…….. ???

ALCHOHOL PRODUCTION – A VIEW

In Maharashtra around 16 industries have received licenses to produce alcohol from food grains, besides to this 210% subsidy has been offered. These industries will produce potable alcohol from food grains, which will be purchased from adjacent farmers & also offer them good rate. This activity will create a whooping quantity of 118 Core Liters alcohol for the 11 crore residents of Maharashtra, which has to be consumed in this state only.

ALCOHOL PRODUCTION – ECONOMICS

For production of 1ltr alcohol, we require 3 kg. of Maize at an average rate of 10/- kg. Average rate of potable alcohol is @ 35/-liter. If the cost of raw material is 30/- and we have to add cost of production & profit of the entrepreneur ,this will not be a viable option, hence a subsidy is required to make this viable, then how one can offer good rate to farmers?. As per available data @ 20% of the total yield of any farm is wasted due to handling, lack of storage facility, losses in transport etc. A single example of wastage of wet food grain in the state Haryana is @ 20 lakhs tons last year.

A SUSTAINABLE OPTION – BIO GAS

To produce ethanol from sweet sorghum or Maize and Molasses from sugar industry is not new to us but we are using ethanol in automotives@ 5 % only. While nations like Brazil are using ethanol 100 % & replaces existing fuel completely.

Since our research & development for last 10 years regarding biogas and its related fundamental parameters such as feeding material & its starch content & the bacterial count for degradation. Time required for degradation and so on. We have concluded the production of Biogas from waste food grain on a commercial scale will be economical, environment friendly and can be applied anywhere in India. Though it needs huge capital investment for infrastructure but we have proved the same can have high rate of returns.

Before going into details of the above mentioned project, we must understand what is biogas & how it can be produced , what are the affecting parameters on it etc.

A simple definition of Biogas is “A gas produced from any starchy biomass under anaerobic condition with the help of anaerobic bacteria.” The most known application is “GOBAR GAS” which produced with the same principle from Dung of Animals.

The affecting parameters are mentioned below.

1. Anaerobic Status of Digester Tank

2. Availability of Starch into biomass.

3. Time required for Biodegradation (Hydraulic Retention Time)

4. Total number of Anaerobic Bacteria

5. Temperature of Digester Tank @ 25C0 (Low Temperature Affects Bacteria’s)

The feed quantity of Biomass into Digester Tank of Biogas Plant is further degraded with the help of three type bacteria’s. Those are mentioned below.

(i) Hydrolytic Bacteria

(ii) Acidogenis Bacteria

(iii) Methanogensis Bacteria

Acetic Acid is formed by bacteria (CH3COOH) which is further degraded and two Gases (CH4) (Methane) & CO2 (Carbon dioxide) are produced in a combination of Biogas.

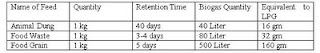

If we consider two different Feed Material for Biogas (a) Animal Dung (b) Food waste. (c) Food Grain. Let us compare the production of Biogas from the table mentioned below.

Earlier residents of rural area, who were using biogas, makes a complaint regarding burning of Biogas. This was true because biogas contains 60 % Methane (CH4) & 40 % Carbon dioxide (CO2) due to the non burning of Carbon dioxide an adverse impact on the flame of biogas resulting slow burning.

At “Shashwat Oorja” Pune with a continuous research and development in the same, we have separated both the gases successfully where the burning of Methane becomes complete & even the calorific value of biogas is increased. As both gases are separated we have successfully implemented their refilling into cylinders which will double the economics of the plant by selling CO2.

As Carbon dioxide has its own usage in different industries like forging, welding, Extraction solvency, Aerated drinks & dry ice, the rates for CO2 also different from 15 to 100 /kg depending upon application.

In these projects, it is not necessary to use good quality food grain, but wastage in grains, low quality food grain, wet waste of food grain can be used to produce biogas. This will become an additional income for farmers though which they will generate wealth from waste. This may be a small attempt to save pollution but will add same cash benefits like Carbon Credit Certificate. (C.C.C.)

Any farmer can install & use these plant. They are Eco friendly and Tech friendly. The farmers can cultivate some of the energy crops in their farm. Such as Tapioca, Maize, Sugar beet to produce highly starchy biomass. This will ensure the high rate for crop at the field / farmer itself. These energy crops produce high quantity of biogas as 900, 500 & 300 liter/kg respectively.

The slurry generated for biogas plant can be recycled in the farm to increase C: N ratio along with N.P.K. contents of the soil which will enhance the yield of crop.

As the 70% of our total L.P.G. (liquefied Petroleum Gas) is imported, we can offer a local & sustainable option of fuel to citizens of India. This will also save high expenditure on resources of our India.